Carecoat Recoseal 10 is a

stone surfaces that are weather-beaten discolored, chalked and/or eroded.

Besides reconditioning of weathered surfaces, Using Recoseal 10 means prolonging the lifetime and extending maintenance/ cleaning intervals.

Why use Recoseal 10?

teak decks, pool areas, deck chairs, gel coatings and deteriorated painted surfaces. With a special pre-cleaner it can also be used to restore cracked plexiglass and polycarbonate windows.

Quick & economic Application

Color recovery

Outstanding UV resistance

Gloss Retention

How to use Recoseal 10

- It is recommended to sand down strongly eroded surfaces for best adhesion and gloss recovery of Carecoat Recoseal 10. Finish with grade 1500 or 3000 for optimal gloss.

- Ensure the surface is cleaned and degreased with a 0,5% – 1% solution of Careclean Multiclean. In case of heavy soot deposits; use Careclean Alkaline. Then rinse thoroughly with fresh water and ensure the surface is really free of any detergent/dust.

- Ensure surface and coating temperature stay within 5°C to 30°C and that the relative humidity is between 45% and 90% (use supplied hydrometer).

- Add CARECOAT RECOSEAL 10 component B (small bottle) to component A (big bottle) and mix thoroughly to achieve a homogenous mixture. The Pot life is approximately 6-10 hours depending on the temperature and relative humidity.

- Apply application pad with blue side to application pad holder and wet the white side of the pad just enough to keep it moist. Wipe with minimum pressure over surface until it is equally and fully covered. High abrasive surfaces could require several strokes with a wetted pad to ensure maximum color and glass recovery.

- Carecoat Recoseal 10 is cured for normal mechanical use and, if desired, a second layer after 24 hours (20-30°C). Maximum cross-linking achieved after 14-20 days. Do not accelerate curing by using forced (heated) drying.

Application time reduction up to 70% compared to traditional (wax) application

Due to the fact the coating is so easy to apply and requires normally only one layer to give the full recovery of color and gloss, the product is ideal to replace the existing treatment with a wax coating. For these coatings it is common to sand down the surface several times, followed by 1, 2 or even 3 layers of the wax. With Carecoat Recoseal 10 it is only needed to sand down a heavily eroded (or chalked) surface with a fine grid sand paper (1500 – 3000) to remove deposits stuck in the top layer. After that just a good cleaning/degreasing and the product can be applied by wiping the application pads lightly over the surface. Alternatively the product can also be sprayed onto the surface but please note that the spray is highly flammable!

Since Carecoat Recoseal 10 does not leave white stains on rubber or dark surfaces, there is no need to tape of other surfaces before applying. All these aspects combined make that you can save up to 70% in application time to get your surface bright and shiny again.

Carecoat Recoseal 10 consists of modified organic and inorganic

micro molecules, giving it the following enhanced properties:

- Low viscosity & highly crosslinked

- Curing at high humidity (≤ 90%) and at low temperature (≥ 5° C)

- Long pot life (>6-10 hours)

- Extreme penetration with optimal adhesion

- Outstanding corrosion-, UV-, salt and chemical resistance

- Exceptional gloss retention and excellent abrasion resistance

- Low adhesion of atmospheric pollution; once applied, easy to clean

- Easy and quick in manual application

- Transparent (not pigmented), does not leave white stains

Application example

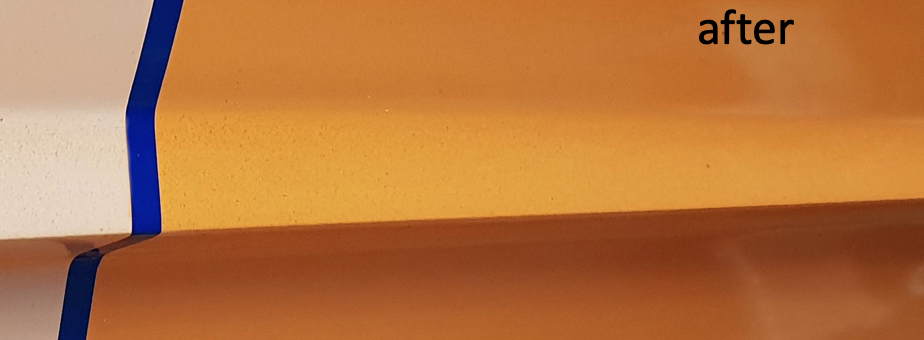

To test Carecoat Recoseal 10 we visited an old lifeboat that was to be overhauled at Palfinger Marine. Normally the crew would grind the surface in 2 steps (abrasive grain 1500 and then 3000), pre clean with degreaser and then polish with a 3M marine polishing product by means of a rotating polishing pad. The 8 meter lifeboat would take 8 – 12 hours to be completely treated.

Just for the sake of the test, we only pre cleaned the surface with a Careclean Multiclean solution and immediately applied 10 ml of Carecoat Recoseal 10. The result was astonishing to the crew, the 0,5 m2 only took 5 minutes to treat and gave a good result. If the surface would have been sanded before application, the result would be excellent.

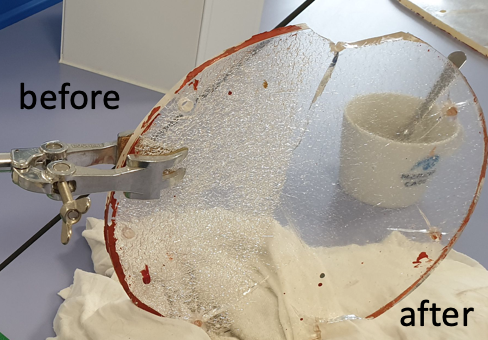

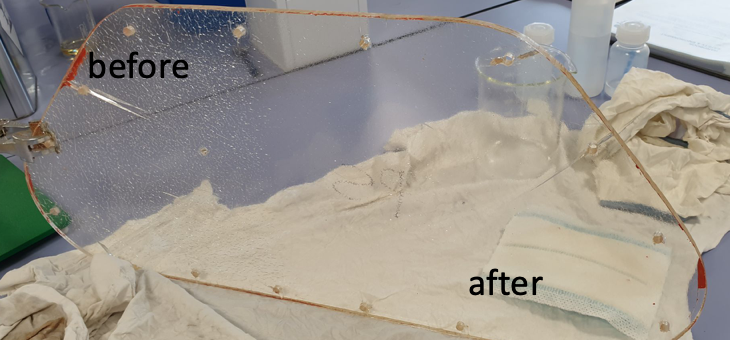

Palfinger’s service crew is frequently confronted with plexiglass windows that show severe cracking due to impact (tests) and/or surface erosion. Since there is usually a lack of time to get a replacement window installed, Carecoat Recoseal 10 was tested as restoration coating for these windows. As the pictures show, it gave a good result and prevents the lifeboat from being rejected during safety check. The solution is now used as intermediate solution until the windows can be replaced during dry dock.

Critical for this application is that the windows are pre cleaned with a strong solvent cleaner (Careclean Precoat).

Carecoat Recoseal 10 is standard supplied in kits or as set (A+B component).

Color

Smell

Commercial Packaging

200 gram kit (incl. 4 application pads).

1000 gram set (only component A + B)

Storage

frost free and dry, 1 - 2 years; Once mixed only 4 - 6 hours!

Type

Viscosity

Pricing & Availability

- 200 gram set (>10m2 <50 m2)

- Application pads, non absorbing, roll 12,5 Meter

- Carecoat Recoseal 10 commercial kit (>200m2 <1000 m2)

- 1000 gram set (>50m2 <250 m2)

- Application pad holder pcs.

Factsheet Carecoat Recoseal 10 Questions:

Application on plexiglass/transparent surfaces

Question:

- Can Carecoat Recoseal 10 be applied on transparent surfaces and if so, will it give any effect?

Answer:

- Yes, it can be applied on transparent surfaces like plexiglass, but the pre treatment must not contain any surfactants. Use Careclean Precoat as surface cleaner/degreaser and ensure surface is dry before you apply Carecoat Recoseal10.

Wet on dry application

Question:

- Can Carecoat Recoseal 10 be applied on top of already dried layers, and if so, will you see the effect of a double layer?

Answer:

- Yes, it can be applied on top of a dried layer (just ensure dried layer is clean). There will be no visible impact, of the two layers on top of each other. A double layer does not make the surface more glossy or restore the color even more.

Head office

Rotterdam, NL

Find the answer to your query here. Don’t hesitate to contact us!

Distributors

THE NETHERLANDS

Marine Care B.V.

Oude Maasweg 35 | Port# 4005

3197 KJ Botlek – Rotterdam

The Netherlands

P: +31 10 29 50 342

E: operations@marinecare.nl

USA

Marine Care Cruise Services, Inc.

Marine Care

Cruise Services, Inc.

2070 Tigertail Blvd., Bld.#2,

Suite D & E, Dania Beach,

FL 33004

United States of America

P: +1 954-922-3585

E: operations@marinecare-usa.com

SINGAPORE

Marine Care Singapore Pte Ltd

7500A Beach Road, #07-306/307

The Plaza 199591

Singapore

P: +65 62 9115 71

E: operations@marinecare.com.sg

SCANDINAVIA

Marine Care Scandinavia AS

Tveitaraasveien 12

5232 Paradis

Norway

P: +47 55 51 0500

E: operations@marincare.no

United Arab Emirates

Marine Care UAE

(Pleasure Craft & Yacht Care)

Dar Al Salam Building

Unit 607 Corniche St.

P.O Box 61606, Abu Dhabi

P: +971 (0)2 674 5941